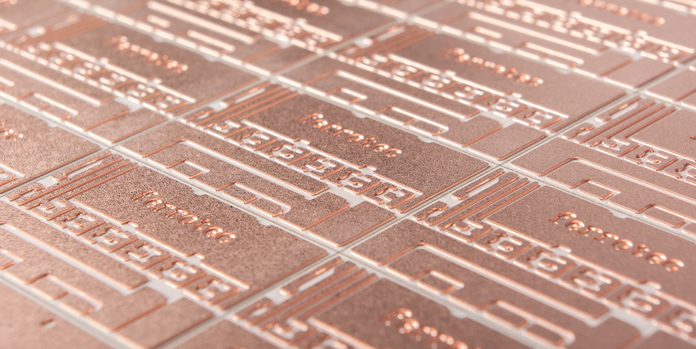

DBC & AMB Power Electronic Substrates

Temperature Controlling Semiconductors (Peltier Elements)

Ferrotec is the fastest growing, worldwide supplier of Direct Bond Copper (DBC) and Active Metal Brazed (AMB) Ceramic Substrates for power electronic applications. Our offering includes Active Metal Brazed (AMB) on Aluminum Nitride (AIN) or Silicon Nitride (Si3N4) and Direct Bond Copper (DBC) on Alumina or Aluminum Nitride (AIN).

Direct Bond Copper (DBC) and Active Metal Brazed (AMB) ceramic substrates from Prototype to Production

Generally, organic and metal substrates are used in the circuit boards of low-power home appliances and computers. However, for high-voltage, high-current applications like, power modules, solar inverters and motor controllers, ceramic substrate materials such as alumina, aluminum nitride and silicon nitride with better thermal properties are needed.

With our expansive manufacturing capability in Asia, local support and third party partnerships, Ferrotec is able to provide high quality support, no minimum order quantity, quick turnaround and a seamless path to low cost, high volume production.

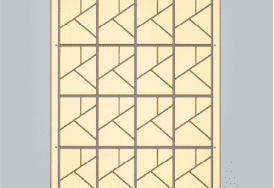

Direct Bond Copper (DBC)

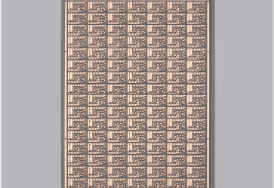

Active Metal Brazing (AMB)

DBC Product Characteristics

| DBC board performance | Item | Numerical value | Unit | |

| Maximum dimension | 138*190 | mm | ||

| Maximum effective area | 127*178 | mm | ||

| Pitch between resists | In line with our design rules | mm | ||

| Resist width | +0.3/-0.2 | mm | ||

| Peel strength | >5 | N/mm | ||

| Solderability | >95% | % | ||

| Shipping form | Individual delivery/MC delivery | |||

| Surface condition | Copper pattern/resist/Ni plating/ Ni gold plating/Silver plating |

µm | ||

| Material fee |

Alumina ZTA | Component | 90% Al / ZrO₂ | % |

| Thickness | 0.32, 0.25 | mm | ||

| Density | 3.95 | g/cm³ | ||

| Thermal conductivity | 27 | W/mk | ||

| Pile strength | 600 | W/mk | ||

| Relative permittivity | 10.5 | 1 MHz | ||

| Dielectric loss | 0.0003 | 1 MHz | ||

| Dielectric strength | 20 | kV/mm | ||

| Volume resistance | 1*1014 | Ωcm | ||

| Alumina | Component | 96% Al₂O₃ | % | |

| Thickness | 1.00, 0.89, 0.76, 0.63, 0.5, 0.38, 0.32, 0.25 | mm | ||

| Density | 3.73 | g/cm³ | ||

| Thermal conductivity | Twenty four | W/mk | ||

| Pile strength | 350 ~ 450 | Mpa | ||

| Relative permittivity | 9.8 | 1 MHz | ||

| Dielectric loss | 0.0003 | 1 MHz | ||

| Dielectric strength | 20 | kV/mm | ||

| Volume resistance | 1*1014 | Ωcm | ||

| Copper | Material | Oxygen free copper | % | |

| Purity | 99.99 | % | ||

| Hardness | 90 ~ 110 | HV | ||

| Conductivity | 58.6 | MS/m | ||

| Thickness | 0.40, 0.30, 0.25, 0.20, 0.127 | mm | ||

AMB Product Characteristics

| AMB substrate performance | Item | Numerical value | Unit | |

| Maximum dimension | 138*190 | mm | ||

| Maximum effective area | 127*178 | mm | ||

| Pitch between resists | In line with our design rules | mm | ||

| Resist width | +0.3/-0.2 | mm | ||

| Peel strength | >10 | N/mm | ||

| Solderability | >95% | % | ||

| Shipping form | Individual delivery/MC delivery | |||

| Surface condition | Copper pattern/resist/Ni plating/ Ni gold plating/Silver plating |

µm | ||

| Material fee |

Silicon nitride | Component | 96% SiN | % |

| Thickness | 1.0, 0.63, 0.32, 0.25 | mm | ||

| Density | 3.22 | g/cm³ | ||

| Thermal conductivity | 90 | W/mk | ||

| Pile strength | 700 | Mpa | ||

| Relative permittivity | 8 | 1 MHz | ||

| Dielectric loss | 0.001 | 1 MHz | ||

| Dielectric strength | 20 | kV/mm | ||

| Volume resistance | 1*1014 | Ωcm | ||

| Aluminum nitride | Component | 96% AlN | % | |

| Thickness | 1.0, 0.63, 0.38, 0.25 | mm | ||

| Density | 3.3 | g/cm³ | ||

| Thermal conductivity | 170 | W/mk | ||

| Pile strength | 350 | Mpa | ||

| Relative permittivity | 9 | 1 MHz | ||

| Dielectric loss | 0.0005 | 1 MHz | ||

| Dielectric strength | 20 | kV/mm | ||

| Volume resistance | 1*1014 | Ωcm | ||

| Copper | Material | Oxygen free copper | ||

| Purity | 99.99 | % | ||

| Hardness | 60 ~ 110 | HV | ||

| Conductivity | 58.6 | MS/m | ||

| Thickness | 0.8, 0.5, 0.4, 0.3, 0.25, 0.2 | mm | ||